OMVE in Africa

Small-Scale Process Equipment for Pilot Plants in the Food and Beverage Industry

OMVE, a Netherlands-based company, is globally recognized for its state-of-the-art small-scale process equipment, serving the food, beverage, and dairy industries. With a reputation for quality and innovation, OMVE sets the benchmark in equipment design and performance.

Industris CC is proud to be the official distributor of OMVE products and equipment across Africa, operating from our primary location in Boksburg, South Africa.

Through this partnership, we provide businesses with access to cutting-edge solutions to boost your business’s product development and processing capabilities, helping to elevate their operations and success.

Select a Technology

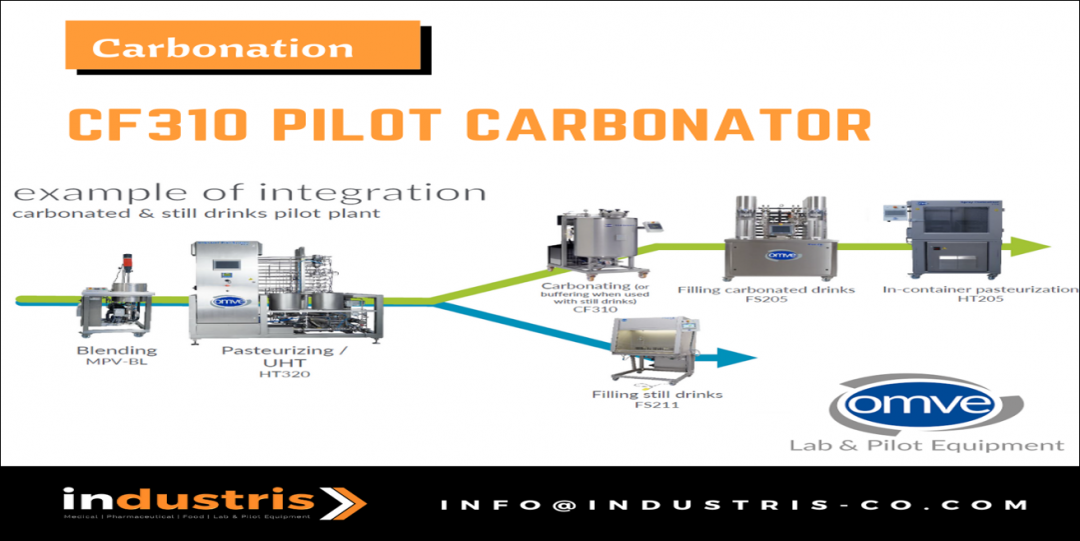

OMVE Technology:Carbonation

Accurate and reproducible

Carbonation is the process of dissolving and binding gaseous carbon dioxide into a liquid. Carbon dioxide is an important ingredient in recipe development and is widely used by producers to give drinks their acidic aftertaste and to add ‘fizz’ to the consumer experience. Being able to test and compare different CO2 levels in a recipe during the early stages of formulation ultimately shortens the time to market. As such, efficiently filling and closing samples critical for obtaining accurate and stable sample products.

OMVE’s carbonator equipment range allows you to carbonate a wide variety of products, from low-viscosity beverages to pulp-based drinks. You can also fill and close various types of packaging, including metal cans as well as PET and glass bottles.

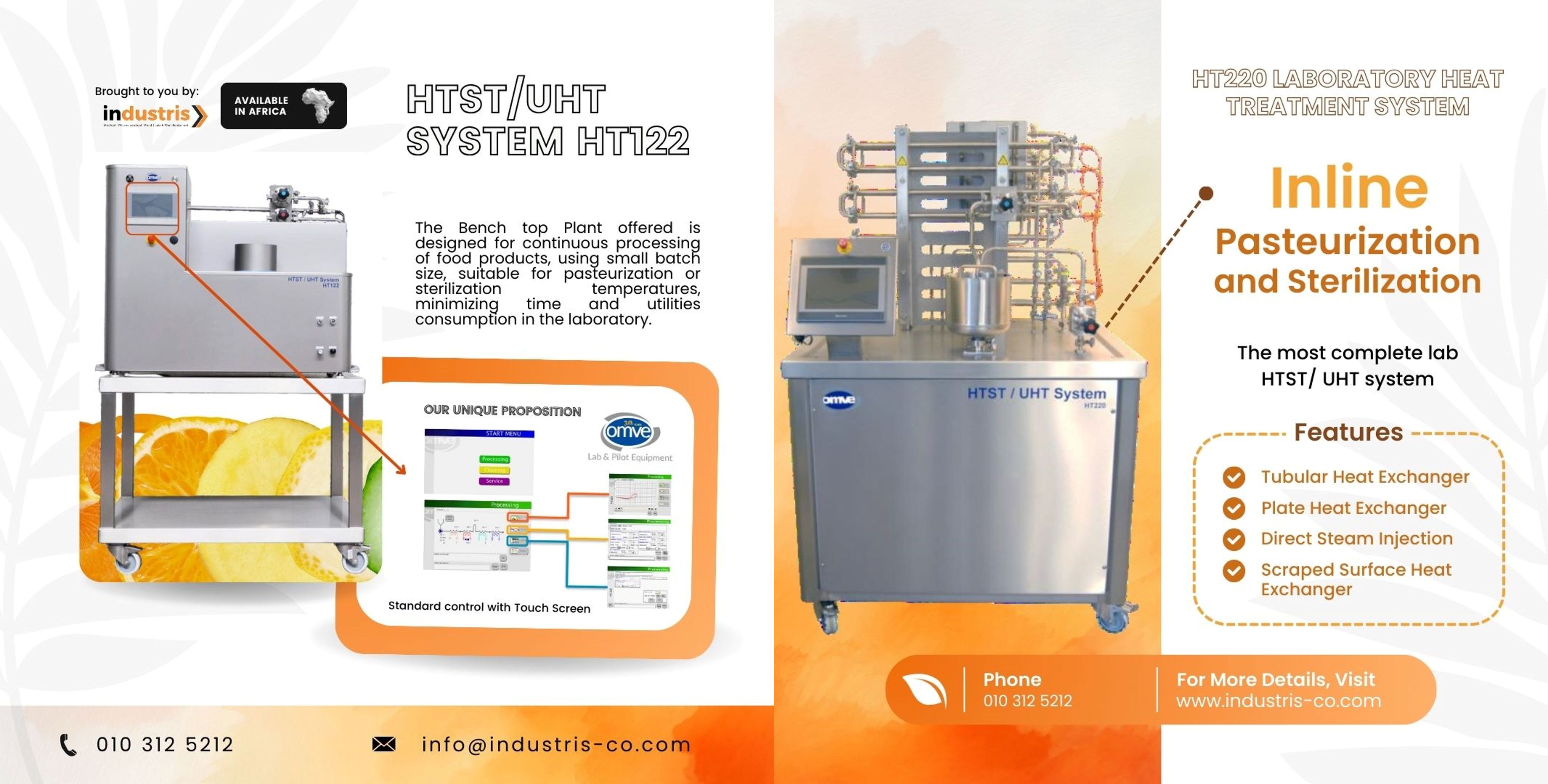

Technology: Heat Treatment

HTST and UHT heat treatment test with a minimum of product

Heat treatment relies on microbial and enzyme inactivation to help extend the shelf life of certain food and drink products and to ensure food safety. However, this process can damage the organoleptic properties of the product. Understanding why this happens from the early stages of formulation, and what the impact will be, can shorten time to market. However, these investigations can prove expensive and highly time-consuming.

Our range of heat treatment systems allows for in-container pasteurization, inline pasteurization and sterilization and batch cooking of a wide variety of liquid products, starting with a minimum batch size of one liter. Depending on the viscosity of your product and the process you wish to replicate, we can provide you with a variety of different heat exchangers (specified below) and methods, including HTST and UHT. Our heat treatment systems have a capacity range of between 10L/h and 1,000L/h.

Technology: Homogenizing

Achieve a uniform structure for your product

High-pressure homogenization offers a number of benefits for your products, including improved taste, texture and consistency. Ensuring the stability of the final product is particularly important for food and beverage producers, as this prevents particles from separating from the solution.

Our range of homogenizers can be connected to and controlled by our pasteurizers and sterilizers or used as standalone systems. This equipment can be used in both an up-stream and down-stream capacity. An aseptic homogenizer is required for down-stream use.

Our homogenizers have a capacity range of between 10L/h and 1,000L/h.

Technology: Filling & Closing

Precise, flexible and hygienic/aseptic

Filling and closing packaging are among the most important stages of industrial production, protecting products from potential contamination. Only samples in their final consumer packaging are eligible for quality studies such as shelf life and consumers tests.

The risk of contamination can be further minimized by using specifically designed fillers. These fillers ensure you get the most out of your test – collecting samples that cannot be analyzed is a waste of raw materials and other resources.

OMVE’s hygienic counter pressure filler for carbonated drinks helps maintain a predefined carbonation level in the final packaging and is easily integrated into the wider carbonation process.

Our solutions allow you to control both the hygienic conditions and the filling and closing processes for cans, PET, HDPE and glass bottles, bags and other forms of packaging.

Technology: Deaeration

Less oxygen, better quality

Pumping and mixing can introduce undesired air and gases that can compromise the quality of liquid food products, limiting their shelf life. Product deaeration – i.e. removing dissolved gases from water, carbonated beverages (CSD), juices, fruit puree and dairy products – offers the following benefits:

- Improved product shelf life and appearance, particularly color

- No oxidation of ingredients during heat treatment

- No impairment of flavorings, colorants or nutritional compounds

- Decreased foaming across all process stages

- Increased carbonation consistency

- OMVE offers a range of inline and batch deaerators that mimic industrial deaeration processes to help you obtain similar results from R&D activities.

- Our deaerators have a capacity range of between 10L/h and 1,000L/h.

Technology: Crystallization & Aeration

Controlling and developing texture

Crystallization and aeration are used to structure and add texture to products such as dairy items and margarine, as well as a range of low-calorie and low-fat products. These processes, which must be undertaken at specific temperatures, can directly affect the texture, mouthfeel and taste experience of the end consumer.

Studying a product’s sensory characteristics demands the systematic evaluation of all process variables and ingredients. This requires panel tests to be performed concurrently to formulation. However, the use of production plants is rarely feasible during these evaluation stages.

OMVE’s crystallization and aeration equipment make it possible to isolate and control all variables, including temperature, shear, kneading and overrun, allowing you to replicate your existing processes and develop new products. The capacity range of our crystallization and aeration equipment is 10L/h to 50L/h.

Technology : Blending & Mixing

The right start

Combining ingredients is an important initial step for many product formulations. This makes having controlled mixing, blending and stirring operations in place essential. OMVE provides a range of solutions for dissolving powders and concentrates, suspending solid fractions, blending components and emulsifying. Whatever your viscosity or required shear, we can supply tanks with the right dedicated mixing facilities.

The blending vessels can be heated and cooled to maximize their dissolving capabilities.

The capacity range of our blending vessels is 10L to 1,000L

Technology : Fermenting

Clean, autonomous, accurate

The market for fermented food products is growing rapidly, and now includes dairy, soy, fruit, vegetables, and many other items.

OMVE’s lab and pilot fermenting equipment allow producers full control throughout the duration of this delicate process. As well as minimizing resources, you will be able to create the right amount of product for conducting shelf life studies and panel tests. OMVE also offers a structuring add-on for yogurt applications, providing the right viscosity and texture from each run.

The process is controlled by different sensors, allowing you to start the fermentation process, set the required parameters and let the system run autonomously. Our fermenters can be connected to an OMVE pasteurizer or UHT equipment and/or filling system. They are cleaning in place (CIP) and sterilizing in place (SIP) ready.

The capacity range of our fermenting equipment is 6L to 400L.

Technology : Buffering

Minimize product losses, increase efficiency

Buffer tanks are an essential part of food-industry production lines, isolating the processing and filling stages of the process. The use of a such a tank minimizes product loss in the event of technical issues and compensates for potential capacity variances. The use of a buffer tank is especially advantageous in combination with a higher capacity continuous machine and a filler – for example, UHT with a nominal capacity of 50L/h with an OMVE filling bench.

We offer aseptic and hygienic buffer tanks in a variety of sizes. The different features include insulation, double-jacket vessel, temperature and pressure regulation, different types of mixing agitating and high or low viscosity product suitability. All our buffer tanks are cleaning in place (CIP) and sterilizing in place (SIP) ready.

The capacity range of our buffer tanks is 20L to 1,000L.

Technology : Batch Cooking

Gentle, controlled, modular

Batch cookers are used for dissolving sugars and powders, extraction, osmotically drying fruit and for the gelatinization of starches.

Our small batch cookers are designed for cooking, mixing and hydration processes. The vessel is heated using hot water, steam or direct steam injection (DSI), and cooled via chilled water or vacuum. Different mixers can be applied during heating and cooling for the purpose of mixing (with a low or high shear), blending or stirring the product. OMVE can provide you with the right batch processing vessel for your specific application needs.

The capacity range of our pressurized batch cookers is 10L to 100L.

Technology : Cleaning-In-Place (CIP)

Faster clean with more convenience

Cleaning in place (CIP) has been standard practice in hygiene-critical industries such as the food and beverage and pharmaceutical sectors for the past 50 years. CIP is principally concerned with soil removal. This process can either be visible – involving fats, proteins, carbohydrates and minerals, for example – or invisible – i.e. involving different forms of bacteria.

CIP requires the use of a chemical surfactants and/or enzyme-based cleaning agent.

OMVE’s CIP solutions can be offered either within the machine itself or as an external unit. Our CIP systems reduce cleaning time significantly, especially when using vessels as part of your process.

Technology : Spray Drying

Traceability, complete control & predicted humidity %

The OMVE SD310 Spray Dryer provides a high quality of spray dried products by controlling and monitoring the temperature and moisture content. This minimizes product loss and makes product development easier and faster. This ergonomically designed system is meticulously crafted to provide you with the best configuration, safety during operation, process control, ease of cleaning, sanitary design, and scalability.

Operators can rely on the high level of automation to reduce the development time of food applications. The SD310 comes standard with several control points and monitors, as well as 15 process parameters. The spray is adjustable, easy to inspect and clean, and can be customized for various spraying profiles. The SD310 Spray Drying pilot plant is the next level for drying products in small scale production plants, R&D labs and universities worldwide.